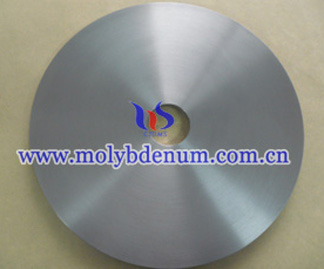

Round Molybdenum Sputtering Target

Purity: ≥99.95%

Density: 10.2g/cm3

Melting Point: 2610℃

Boiling Point: 5560℃

Shape: round

Properties: round molybdenum sputtering target has high strength, great high temperature creep and the inner organization of it also very even.

Application: the round molybdenum sputtering targets are wildly used in conducting glass, STN/TN/TFT-LCD, optical glass, ion plating and other films.

Purity Require: High require is an essential performance of molybdenum sputtering target. The purity is higher the sputtering films performance is better. Usually, the molybdenum target purity require is 99.95% (mass fraction, the same below), but with the development of LCD industry the requirement of glass substrate size increase the wiring’s length is required to extend and the line width is required to fine. Besides, in order to guarantee the uniformity of films and quality of wiring also need to improve the purity of target. So according to sputtered glass substrate size and using environment the purity requirement of target is at 99.99%~99.999% or even higher. Molybdenum sputtering target as cathode sources during sputtering, the impurity of solid and oxygen and moisture of air hole is the main pollution of deposited film. Besides, in the electronics industry, due to alkali metal ion (Na+, K+) in the insulating layer easy become mobility ion to reduce the properties of products. Aranium, titanium and other element will release radial making products have some soft breakdown effect. Iron and nickel icon will increase oxygen content and it also will make interface leakage. So when product molybdenum sputtering target should strict control these impurities.