Properties of Molybdenum Sputtering Target

In order to increase sputtering efficiency and ensure film deposition quality, properties of Molybdenum sputtering target are required in a high standard.

Purity of Molybdenum sputtering target

High purity is fundamental requirement of molybdenum sputtering target. The higher purity molybdenum sputtering target is, the better performance molybdenum sputtering film deposition. Generally speaking, the purity of molybdenum sputtering target should reach 99.95% at least. With the development of LCD and electronic industry, purity of molybdenum sputtering target will be 99.99%--99.999%, or even higher.

During sputtering coating, when Molybdenum sputtering target with low density is hitted, gas in gaps of target would be released. Thus, quality of molybdenum sputtering target is lowered. So, to molybdenum sputtering target, density is required above 98% to better performance target sputtering film deposition.

In general, Molybdenum sputtering target is polycrystalline structure. Size of die is measured from micrometer to millimeter. The smaller size the die is, the higher speed sputtering. And its distribution is balanced.

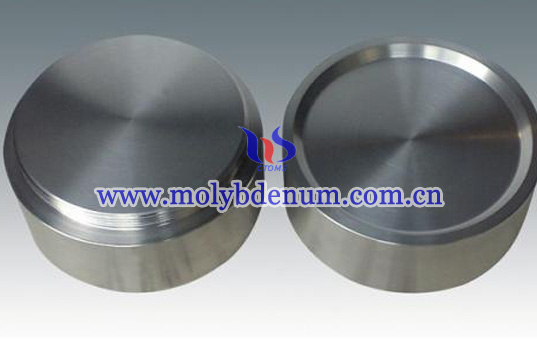

Bonding of target material and chassis

Molybdenum sputtering target is bonded with copper or Al etc. to ensure good conductivity of electricity and heat.