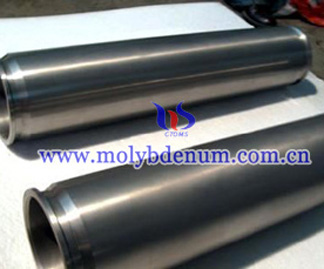

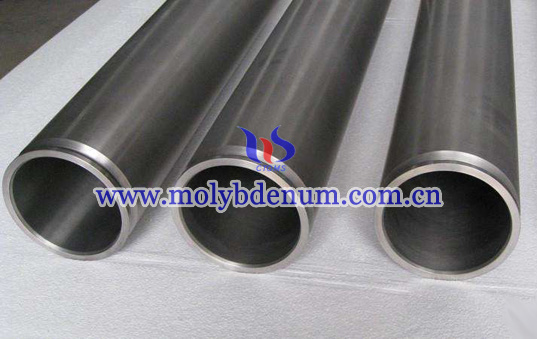

Rotating Molybdenum Sputtering Target

Rotating molybdenum sputtering target is a magnetron target. The target is usually made into cylinder type and there are stationary magnets in the target rotating slowly.

The using temperature of rotating molybdenum sputtering target is 1800℃ and maximum service temperature is 2310℃. Besides, the density of it is 19.2g/cm3 and purity is 99.95%.

Rotating molybdenum sputtering target has low specific impedance, great corrosion resistance, high conductivity and high melting point. And it is widely used in quartz smelting, glass smelting, vacuum furnace, high temperature furnace and as plate electrode of thermal insulation material and other fields.

Rotating molybdenum sputtering target can improve molybdenum sputtering target use ratio. Compared to some plane molybdenum sputtering target the rotating molybdenum sputtering target can show the obviously advantages. Due to some change of geometry and design the rotating molybdenum sputtering target usage rate improve greatly. For example, the plane target usage rate is 30%~50% and rotating molybdenum sputtering target’s usage rate is more than 80%. On the other hand, the use-life of target can defined as sputtering power multiplied with sputtering time or the thickness of deposited material in substrate. And if the use life of target mean sputtering powder multiplied with sputtering time then the use life of rotating molybdenum target is 5 times long than plane molybdenum target. What’s more, because rotating molybdenum sputtering target continue rotate during sputtering so there will not have heavy sedimentation phenomenon.